Barracuda 200ZW v. Sailrite LSZ1

For the past 25 years and more I’ve dreamt of owning a Sailrite. This is the sewing machine that everybody in the cruising community talks about, because, they say, it can romp through eight layers of heavy-duty terylene cloth. For independent-minded liveaboards who want to be able to mend their sails mid-ocean or make dodgers and awnings, such prowess is invaluable.

Having waited for almost three decades to encounter a second-hand machine, I finally gave up. I finally decided that I would have to part with $1,250 US + shipping (£1,230 from a UK supplier) for a new one. But whilst searching for Sailrite’s website, I stumbled across a cut-price alternative: The Reliable Barracuda.

(If you want to avoid the novela and cut straight to the chase, scroll through the next four paragraphs.)

When I first joined Nick and started cruising, I brought along an old Singer. This machine was given to my mother on her 21st birthday and had been her most treasured possession. It was not one of those antique beauties with goldleaf decoration and a hand-operated mechanism; rather, it was Singer’s first electric machine, and a state of the art device – in 1939.

Mum was the daughter and grandaughter of seamstresses – even her aunts were seamstresses – and she used her Singer 201 all throughout my childhood, making dresses for her girls and on one occasion turning out a canvas cover for the family’s Wayfarer dinghy. I can still recall the anguish involved in that latter undertaking… because redoubtable as it was, the poor old Singer still baulked at such heavy-duty work.

When the machine came to me, I used it to make cushion-covers and dresses, and I transformed African batik-printed cottons into kiddy’s clothes, but I never attempted anything major. I was very aware of the Singer’s limitations, and after it was written off as a result of our Southern Ocean ‘shipwreck’ I upgraded to something more suited to the life on the ocean wave. I bought a second-hand Husqvarna Viking.

Now – the Singer was a cast-iron creation and it lived in a stout wooden box. Meanwhile, the Husky’s workings were housed in plastic, and the box was scarcely worthy of the name; it was a cloth-coated cardboard affair. At first glance this made the new addition to the family seem less worthy than its predecessor. However, unlike the Singer 201 the Husqvarna Viking was capable of doing zig-zag stitch; and my particular machine was equipped with an add-on walking foot, enabling it to cope with several layers of thick cloth. That, at any rate, was what the salesman told me…

Husqvarna started out making rifles and shotguns, and another arm of the company now makes motorcycles and chainsaws. This somehow implied, in my mind, a rugged construction – and I accordingly worked the Husky to death. True, I did once manage to use it to repair a torn mainsail; and it did manage to sew through cloth-reinforced PVC, enabling me to knock up a rather rustic sprayhood. But it was only capable of these feats because of that retro-fitted walking foot; and the hard work bent the needle-plate and dented the bobbin. Furthermore, the plastic casing did not endure when someone sat on the flimsy box.

By the time it reached the end of its life, the Husky’s foot was held together with sellotape, and the presser-foot (which pushes down on the cloth) was held on with whipping twine. Even so, it took me quite some time to persuade the skipper that we needed to invest in a proper machine, capable of sewing through several layers of 10oz cloth without cajolement. $1,250…! (£1,230 from a British supplier.) In England, you can very easily buy a perfectly roadworthy second-hand car for less than a quarter of the price of a Sailrite LSZ1; and that same sum also represents more than a tenth of our annual cruising budget. No wonder the skipper had to be bullied for a decade before he would agree to the new purchase!

And then, just when I’d managed to beat him into submission, we chanced upon the Reliable Barracuda.

Barracuda 200ZW v. Sailrite LSZ1

It turns out that legendary LSZ1 is not manufactured by Sailrite; it’s manufactured by a Chinese firm. And the Barracuda appears to be made in a near identical fashion, also in China.

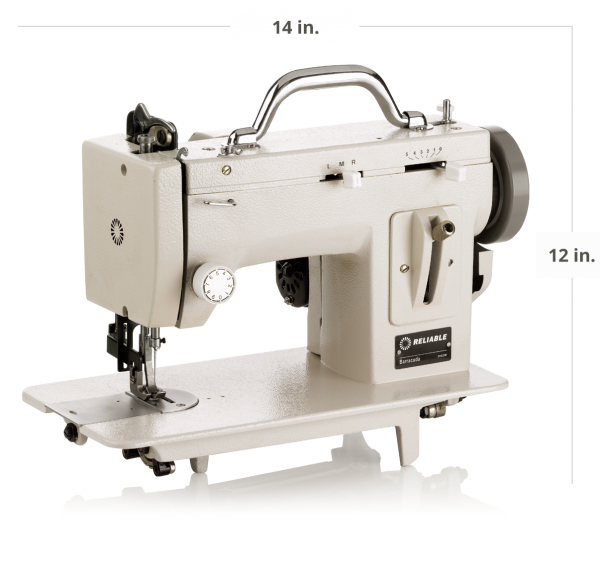

Whereas the basic LSZ1 costs $800, including an MDF pseudo-wooden stand (but no case), the Barracuda is available without any extras (no case; no stand) at a cost of only $500.

If we include the case – a very robust affair, which incorporates a stand, in the usual way – then the Barracuda is a whopping great $550 cheaper than its rival. It costs only $700 whereas the Sailrite costs $1,249

To be fair, this second package includes a hand crank (it’s that black circle in the photo above) and it includes an extra foot, designed for sewing piping, and a DVD. But the hand-crank only costs $125 – or $110 if you buy it from Reliable – and the extra sewing foot and the instruction DVD obviously can’t be worth $440 US!

(Both of these ‘full packages‘ include an LED light, extra bobbins and needles, a zipper foot, and sundry other bits and bobs.)

With or without the box, the Reliable Barracuda sewing machine comes with a three year guarantee as compared to the Sailrite’s two years.

Studying photos of the two products online, I could hardly detect any difference apart from the colour. So… after agonising and dithering for a week, we decided to take a leap of faith; and very shortly thereafter one Reliable Barracuda was on its way south to us.

Let’s not go into the details of how hard it is to get something like this into Chile and how expensive. For most readers this will be irrelevant – so let’s get to the nitty gritty:

Does it work? Is it a good’un? And is it really a Sailrite clone?

The answers to these questions are yes, yes, and pretty much.

I must confess that when I first set eyes on the Barracuda I was disappointed. Compared to the Husky or the Singer, it seems crudely made. The various levers and cranks appear to have been stamped out, the ‘innards’ are on show, and the general effect is of a Heath Robinson machine. However, the proof, as they say, is in the pudding.

The Barracuda’s first job was the creation of new cushion covers. These were to be made from a relatively lightweight cotton cloth, and the Sailrite and Barracuda are both advertised as being suitable for medium to heavyweight work. I therefore anticipated some difficulty – but I had absolutely no problem getting the tension right, and there was no puckering of the cloth. The Barracuda is a lot noisier than a domestic machine – it clatters rather than purrs – but the stitching was perfectly neat and even.

Both the Singer and the Huskqvarna had required much tweaking and a fair amount of swearing in order to get the tension right, and the stitch length on the Husky had varied according to how fast the cloth was passing through the foot. Thus, my initial disappointment was quickly replaced with enthusiasm. Appearances matter little if the thing works!

Nick subsequently had a play with the machine, using it to make a ‘porch tent’ to hang on the back of our sprayhood/dodger. (A transparent ‘porch’ is highly recommended for anyone cruising in southern Chile. It keeps the rain out of the cabin and provides a space in which to leave the perpetually damp coats.)

Next came the sort of job for which we had acquired the machine: The repair of our mainsail after it suddenly tore in two in a squall. This involved sewing through a tight wodge of tough terylene – and not on the edge of the sail but in the middle. In fact, there were places where we had to remove the presser-foot in order to pass a bolt-rope under and get the job in place.

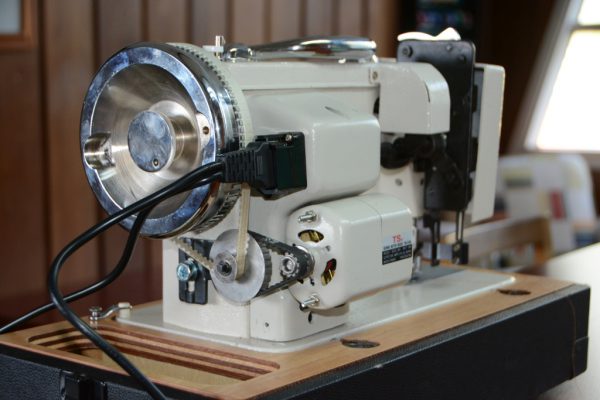

According to the word on the grapevine, these machines are only capable of such very heavy-duty work when converted to hand-operation. Both companies sell an accessory consisting of a hefty metal fly-wheel which engages with a plastic drive-belt – Barracuda call it a Cuda Crank and Sailrite call it a Monster Wheel – and the use of this ‘extra’ not only makes it possible to operate the machine by hand but also slows the motoring speed and thereby improves control. However, at this stage in the game we didn’t have the accessory.

There we were, a couple of hundred miles from the nearest road or the nearest telephone mast, and with our principal means of propulsion lying in two shaggy-edged pieces! This is the sort of problem that we had in mind when we ordered the Barracuda – and yet we were without the vital piece of kit. Damn!

But while I bewailed the lack of the Cuda Crank, the boys humped the sail down into the cabin. (No mean feat; it weighs more than me.) Having spread out the damaged area, they took measurements and cut long thin patches to sew on either side of the sail.

Sitting the new machine on the cabin floor, they then proceeded to repair the sail, Caesar taking charge and operating the pedal, whilst Nick helped to feed the material under the arm. As you can see from the photos, it was a tight fit (the arm is only 7” long), and if the tear had been just a little bit higher – at the position of the second reef instead of the first – we would have needed to remove the lower panel(s) of the sail.

Despite the fact that we didn’t have the ‘cuda fly-wheel, the machine rattled along, producing a perfect zig-zag stitch. My only criticism here would be that the Barracuda only allows one stitch on each zig or zag, whereas the old Husqvarna Viking had allowed up to three; but, then again, even with the add-on walking foot, the Husky could not have coped with even half the thickness of cloth involved on the leech, whereas Barry went through it as if were butter. The integral walking foot feeds even the bulkiest pile of cloth through the needle at a steady pace. For a domestic machine to be capable of such work is nothing short of amazing!

The foot lift is 9mm, and it would seem that you can sew through whatever can be jammed in that space. According to Reliable, their machine can do up to 800 stitches per minutes when zooming along a straight seam. Personally, I prefer to take things at a gentler pace, but this figure gives some idea of the available power.

Mending the sail by hand would have taken a week – a thing which we well know, having had much practice in this matter – but with the help of the Barracuda the job was done in a day.

I have to say that at this stage I was still under the impression that the Reliable Barracuda was a cheap imitation copy of the Sailrite. The quality of the construction does not match that of the old, Edwardian Singer; and if the Husqvarna was a family car, the Barracuda is a tractor. Mind you, although a Datsun or a Chevrolet is comfier and a bit prettier than a tractor, you’re not going to be able to use it to cross a ploughed field. Horses for courses, as they say.

Even so – as I say, I assumed that the machine which cost an extra $440 US must surely combine the power of the agricultural beast with the finesse of… well, maybe not a Porsche, but a Volvo.

Then I met one; and I found that my Reliable ‘Barry’ and my friend’s LSZ1 were almost identical.

Twins

At first glance, the two machines are identical apart form the colour. The Barracuda is a rather boring plain white, and the Sailrite is blue.

(Caveat Emptor: There is a cheaper Sailrite model which is red – but that one doesn’t do the zig-zag stitch which is reckoned to be essential in making or repairing sails. A friend bought one by mistake and regretted it so much that he dumped the machine.)

Let battle commence!

The levers and wot-nots are all in the same place on both machines and are labelled in much the same way. I’d been surprised to find that Barry’s stitch-tensioning knob is marked with nothing more than a stick-on paper label – and I was astonished to find that the much more expensive machine was kitted out in exactly the same way. This may sound trivial, but when you get the machine out of the box this is one of the first things that the eye falls upon, and it screams, “Tacky!”

I also dislike the fact that there is no scale adjacent to the stitch-length lever – and, again, this applies to both machines; there is no way of knowing where the lever was set just before you moved it to perform a reverse stitch manoeuvre. Of course, one can very easily resolve this matter with a permanent marker; but if I were marketing the machine it would have plastic scales glued onto the knobs and levers.

As we have seen, both machines are available with heavy-duty cases. My Barracuda’s box is made of plywood whereas the box housing my friend’s Sailrite was of MDF. This is something to consider if you live on a boat, because MDF does not fare very well when it gets wet.

(Edit: I am told that the most recent batch of Barracudas is supplied with an MDF box – but after reading this remark, the company is now reverting to the use of plywood. So, this is evidently an organisation that listens to its customers!)

The machines sit inside the lower half of the box, in the usual fashion; and adjacent, to the right of the machine, there is a compartment for the cotton and the scissors and what have you. Again, it’s a trivial thing, but I think the machine would look a lot smarter if this compartment had a lid – and neither machine is so equipped.

The Sailrite is supplied with a slender but very useful, well-illustrated booklet describing the operation of the machine. My Barracuda was only equipped with a rather inadequate leaflet – and this is actually quite a big deal. As the reader will have gathered, I’ve done a reasonable amount of sewing; and yet I still managed to mis-thread the machine. It still worked, but the tensioning spring sprang off and broke. It was only after I read my friend’s booklet that I realised that the spring was not faulty and I was to blame for the mishap.

Reliable were very prompt in supplying a new tensioning spring at no cost; and it seems that they have also now produced a rather better set of instructions. They have also produced a short but very useful video which demonstrates how to thread the machine.

With the two machines sitting side by side on the table where we were working, the cable supplied with the Barracuda’s electric pedal was not quite long enough to allow the foot to sit on the floor; I had to put it on top of a book. This pedal is another very tacky thing. It’s made of a rather tinny metal, and you have to press it right to the floor to operate the machine – BUT – I note that my pedal is different from the one shown in Reliable’s adverts. Their adverts show a plastic drivefoot which is identical to the one sold with the Sailrite; and the company say that the lead is usually 6ft long (whereas mine is only 4ft). So, it would appear that they have already rectified this annoying fault.

The Barracuda is fitted with a metal handle, on top of the machine, which makes it easier to lift. There is no such handle on the Sailrite; to lug it around you have to pick it up by the arm. These machines are very heavy – far heavier than the old Singer – so this is a very useful feature.

Neither machine is fitted with a light. I’m not sure why this should be, since a light is almost essential, particularly when you’re working in the cave-like confines of a cruising yacht’s cabin. Even the old Singer had a mains lamp, made from bakelite. As has been mentioned, if you buy the ‘full works’ package (from either company), a light is included. This light has a magnetic base which sticks to the machine’s metal casing.

Sailrite also sell their light separately for $40. (It looks a lot like one which is available on Amazon for under $13 US – but it probably has better LEDs.) Reliable sell various lights, including a superb Uberlight – by far and away the brightest LED that we have on the boat. (See above: the photo of the machine making its debut).

Sailrite claim that some of their machine’s parts are made from a higher quality metal than the cheaper machine and that they are also more precisely made. Having lifted both machines and peered underneath, at the mechanisms, I would say that these differences are not obvious.

We initially thought that we had detected a significant difference between the size of the two electric motors, but upon further investigation they both seem to use the same one (TM2150A), made by a Taiwanese company.

The machines are both available with either a 110v or a 240v motor and plug.

Why does the Sailrite cost almost twice as much as the Barracuda?

That is the $440 question!

I think that, as much as anything, the big-name brand costs more for the same reason that a Gucci handbag or a Lacoste T-shirt costs more than similar items in Tescos or Walmart. Then again, Sailrite fans will tell you that they’re paying for the extra service that you get from that company.

Sailrite make much of the fact that they carefully oil and run-in their machines before they despatch them. Certainly, a new sewing machine does need this TLC – if you don’t oil it, it will jam up – but do you really need to pay someone else $440 to do the job? The instructions sent with the Barracuda do cover this simple task, and there is also a short video. Besides, Sailrite are not the only ones to have a quality control department. The Reliable Corporation also do a full inspection and a test-drive (or “sewing off”, as they term it) for every Barracuda which leaves their factory in Toronto.

Sailrite fans also like the fact that the company is a family-owned business and has been selling sewing machines to DIYers since 1969. But Reliable is also a family business! The current MD is the son of the founder and the grandson of a tailor; and the company has been selling sewing machines and other ‘garment industry’ machines since 1955.

Robert Kahn started working for his father’s business when he was just 13, and some of his employees have been with Reliable for 40 years. So, this is not just “some knock-off company”, cashing in on the success of the big-name brand; in fact, if anything it could be said that it’s the other way about!

Reliable evidently aim to live up to their name – and in my limited experience of the company, they do.

Sailrite’s other big selling point is the instructional videos which they produce. They also run an online forum where sewers can discuss their problems. The good news is that you can gain access to all of this wisdom and knowledge without forking out the extra dosh. The forum is open to all comers. And Sailrite have put the videos up for free on their website – perhaps out of the kindness of their hearts but more probably in the hopes that people will buy the necessary materials from them. (Sailrite also sell Sunbrella cloth, webbing, eyelets, a hot knife, and all sorts of other very useful things.)

Here are three very useful Sailrite videos:

How to make forepeak bunk cushions (1hr 8mins)

How to make a mainsail cover (48mins)

How to make a dodger (or sprayhood, as we call them in England) (1hr 5mins)

And here’s a static page, explaining how to make a Jordan Series Drogue.

Sailrite also sell DVDs and books to assist with sewing projects. If you’ve saved yourself $440 by buying the Barracuda and the Cuda Crank, you could probably buy the full set of books with the change, and still be quids in.

Reliable have also produced a few videos. One provides a quick presentation of the machine. Others demonstrate the adjustment of the needle tension and the bobbin tension (lower thread), and the adjustment of the needle height. There are also videos which describe basic procedures such as how to do a zig-zag stitch and how to thread the bobbin.

If you don’t need the stout wooden case, you can save another $100 by buying the Barracuda in a plastic case. (You still get the light and the other goodies; only the case is different.)

And if you already have a suitable box and stand from a previous machine, then, as we noted previously, you can buy it without any extras at all, for only $500.

Doubtless, if you have the luxury of keeping your sewing machine installed on a dedicated table then there are even more powerful, even heavier, much pricier devices – with a longer arm and the ability to sew through even thicker piles of tough cloth; and, in fact, Reliable also sell such machines. You can even buy one with a 20″ arm! But for those of us who live afloat in small boats, and for others who are travelling or who simply want a compact but very sturdy machine, the Barracuda seems to be about as good as it gets.

When I finally get round to making our new sprayhood/dodger, I’ll post some photos of the undertaking and let you know how the machine copes with this project.

Has disaster struck…..???

Where is the favourite sea gypsy family…..???

Thank you, thank you, thank you for this apples-to-apples review of the Reliable & Sailrite sewing machines! You just saved me a whole bunch of money!

Thanks really helpful review

I know money is always an issue, but here’s something to consider. If the machines are pretty much identical and they’re both manufactured in China who do you think appropriated the design?

I have a Sailrite machine and I don’t in any way represent them. I just don’t really like the idea of supporting a company that is profiting off someone else’s design.

Just my opinion.

Should we all.be driving model t ford’s then ?

Actually Sailrite “appropriated” the design from Thompson, and in doing so they sent the design overseas to china, who then also were able to reproduce it in other brand names.

Probably not a good idea to try to ride a high horse in modern corporate times.

I too made the Baracuda mistake about 7 years ago. Yes, I said mistake. I do a project on my machine about once a year, so its not getting a lot of use but I have more than gone through the money I “saved” buying parts to keep my Baracuda running. Getting parts from Reliable takes f o r e v e r and a day and after replacement parts also broke, I started buying parts from Sailrite (yes, most parts are interchangeable). However, what I found was that the cheap stamped or pot-metal parts from Baracuda were re-engineered by Sailrite and more often than not, a new part from Sailrite shows up as a nicely machined part or gussetted in the place that was week on the old part.

Does the Baracuda work… yes. Is it made on the inside the same way as a Sailrite, my experience tells me it is not. I’m saving my pennies to hopefully replace it with a Sailrite soon as I’ve had enough.

Not trying to be negative, just pointing out that sometimes looks are not everything. Like people, its what’s on the inside that counts.

I second this. I own a Sailrite and recently sat down at a Baracuda thinking I might buy it second hand to have a back up. When the zig zag didn’t work I flipped up the machine to see that one if the metal parts had literally crumbled.

I find the review as posted to be frilly and lacking in technical depth.

If you plan to use your machine the difference in price is well worth it as with any quality tool.

“If you plan to use your machine the difference in price is well worth it as with any quality tool.”

The difference in price argument only apply for the North American folks.

A Pfaff 1245 equipped with a 250watts mini taiwanese motor to make it portable is around 2200€ when a Sailrite cost a European (with shipping and import taxes) around 1900€.

Try to put a 250W motor at the back of a Sailrite… you’ll see that the parts can stand the torque and power.

The sailrite is a hype among the sailing world niche…. many machines with a tiny motor at the back can do way better than a nautilus blue chinese made machine.

I went even cheaper and bought a direct from china family sew. I’m on my 4th sail and have only upgraded the needle bar set screw which had a flat head which stripped. The sailrite replacement was a hex key for better torque.

By the way sailrite “stole” the design of this machine from Thompson.

can you tell me the web address of the “family sew” store, I might do the same.

Greetings

Not sure what Joe is referring to, but I got my MK309 (9″ arm versus 6″) w/ monster wheel (I specifically requested it) from

“DongGuan Myekoo Industrial Equipment Co.,Ltd” on Alibaba.com. Shipping was expensive to US but it arrived very quickly. I wonder if I made a mistake and should have asked if they had any cheaper shipping. Live and learn.

All in, $529.64 with import duty and shipping.

I can’t comment on the quality of the machine yet as I’m a newbie to sewing and don’t even know what I don’t know yet.

I also see Singerman12 on Ebay offering similar but Omega branded machines at similar prices.

One distinction with the Sailrite is their default presser foot has a cutout for accommodate welting. From what I can see the foot doesn’t have that cutout and I will need to get one for my application. Probably from Sailrite, and hopefully it fits.

I’m sold. Been looking at the Sailrite zigzag for a few years now. Just can’t see myself paying that price. I told my cousin about it. And she bought one right away. So, I guess we will be doing a side by side comparison soon.

Her Sailrite

My Baracuda

Thanks so much I really appreciate what you did here.

Dawn

I bougt a sewingmashine that looks like your . ( Secondhand from a german boat in Langkavi). It is named as Singer 2KU33

A close friend of mine had a tour of a Sailrite facility – apparently Sailrite also replaces a couple of key components that often break on the Chinese sewing machines they receive in. They replace them with components of much longer life cycles. Add that to the machine testing, oiling and run in and it could make more sense for the Sailrite variant.

Well, as a costumer we are always researching and think you’ll find their history on their website helpful. Especially when they worked directly with Thompson and they both hold the patent for the ultra feed! So they didn’t steal or appropriate but actual partnered with Thompson.

Most of the “look-a-likes” were made from their old castings from the (let’s say devious) ex-makers of their original Taiwan manufacturer. Before their patent went through their designs were stolen. They sued and won but these people are still illegally making the machines. They aren’t made out of the sturdier metal to be able to withstand the muscle of the machine so beware if you slap a monster fly wheel on them. You can also go on YouTube and watch a video where they compare parts. There is a HUGE difference in the machining of the parts. Companies like Consew have been around and I have used their machines and are decent. I honestly would try that against a Sailrite but they even looked at their machines to improve on them.

I can’t remember not ever sewing in my life and learned on a cranky sewing machine. My graduation gift was a walking foot Pfaff creative 1472 (they have still held their value if you can find one)! I’ll tell ya after you sew on well made machines you will never go back to crappy machines (most of mine were made in Germany). The last thing I want to do is mess with timing, wonder what a weird noise is coming from, do some crazy mods that end up costing just as much etc. I now understand why the reviews for the knock offs are either great or terrible. It all depends if you get one that the holes were put in the right place!

Time is money. I’d rather spend it sewing than cursing at a cranky sewing machine! Lol!

https://www.sailrite.com/ultrafeed-history

Hi Jill 3 years after you wrote this article and with experience, do you still think that Barracuda is the same as Sailrite or after 3 years of use do you think there are differences ?

I’m considering buying one of the two but I still have many doubts.

Thanks in advance

I believe a major difference that was overlooked here is that the Sailrite does a 3 point zig and zag.

I’ve heard a lot about the internals not being as good on the barracuda as well.

Interesting article and the comments raise the usual issues, all true. The issue, for me, is not whether Sailrite is a better sewing machine, but how good is good enough for my needs. Mercedes makes a better car than Chevrolet, at higher cost, but not everyone wants or needs a Mercedes. So each machine has its place and meets the needs and means of a certain clientele. Just as it should be. You seldom get more than you pay for and you are ahead of the game if you actually get what you pay for. Each to his own.

I had trouble with the Reliable Barracuda from the get-go…altho the stitches are great and tension easy to set, there is a definite delay with the foot pedal and actual motor starting..and the bobbin plate was so tight and crudely made in its seating, I had to use a screw driver to pull it open…the housing is rough and crudely made….several nicks in the gulley where the take-up lever is actually caught and broke my thread….I got sick of worries…sent off for repair at their cost because still under warranty…when I got it back the housing over the wheel area didnt even fit and the screw hole was broken…if it was in place correctly, it would have rubbed the wheel…so i know they put the wrong part on..and they did not address the nicks, bobbin plate problems…I finally got pissed and they are sending me a full refund…nagging paid off…dont get it…I went and bought a consew instead (both are portable industrial machines with zig zag)….I have a straight stitch Consew and it is a dream…for under 500…but need the zig zag…why i didnt get the consew with zig in the first place made me the idiot….